My MOC display page

It seems everybody that has been into Lego trains for some time

has the legendary blue Hopper (#4536). Those of us that do not

yet have one or more of these infamous sets have to resort to

scouring Ebay or shamelessly attempting to build a copy from their

spare parts collective. I, being the latter, have come up with

an interesting method of getting around using the exceedingly

rare inverted corner pieces.

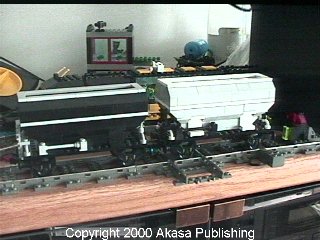

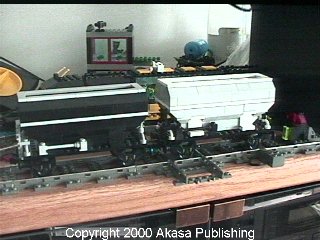

Here you can see my completed version of my gray, black &

white inverted Hopper. At first glance this Hopper looks like

any other clone but it has one interesting fact. It uses no inverted

pieces whatsoever. This includes the corner pieces. The section

that looks like it contains inverted pieces is actually inverted

itself.

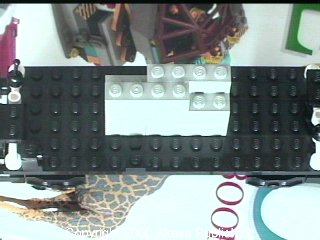

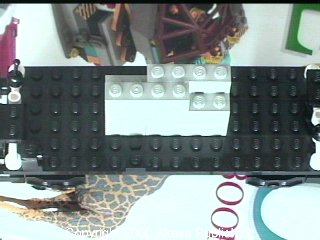

The inverted Hopper is primarily made up of the three segments.

The base segment contains the standard wheel sets, end ladder

assembly and a centering stabilization column that the second

segment attaches to.

The middle segment is built roughly inverted to the standard

Hopper portion. The end studs on the bottom are capped. As you

can see in the photo the assembly is attached to the base by a

technic 1 by 2 brick. The other end is a 2 by 2 with pin.

One side is then inverted and attached to the centering column

on the base and into the wall on the second segment. Due to the

half plate offset caused by the caps on the studs (between the

base plate in the Bottom of the assembly) it fits perfectly to

the half plate offset caused by the pin inversion.

This however created a new challenge of attaching the top

piece (studs up) to the rest of the assembly without leaving a

half plate gap between the two. Also because of the needed centering

column on the base I installed a black bottom to give the illusion

of the dark empty space. This is supported on each end and sits

(with a half plate space) on the centering column supports.

In order to make as snug a fit as possible between the second

and third segments I used the technic pins with stud to secure

the segments together. This worked surprisingly well.

You then simply push them together.

Due to the half plate offset I had to raise the sidebars by

one plate.

Here you see the completed model. The one other thing to note

is the 2 by 2 thin wall (white) are attached to the inverted portion

of the assembly. I then used a 1 by 2 Cap (white) to finish off

the bottom.

In the end I think it turned out rather well.

Copyright 2000 by Akasa

Publishing - All

rights reserved

[RETURN] to TFM's

Home Page